As pioneers in the industry, we offer a comprehensive range of injection molded magnets, including injection molded NdFeB magnets, injection molded SmCo magnets, and injection molded ferrite magnets.

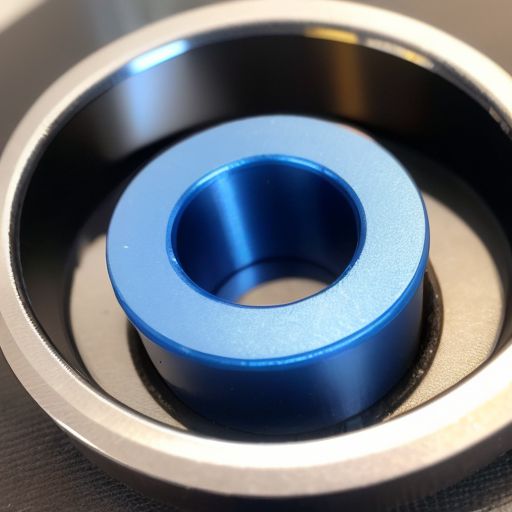

Injection molded NdFeB magnets offer a combination of steel-like strength and flexibility, allowing for thin-walled shapes such as rings, bars, and even more complex designs. By embedding magnets and other metal components (such as gears, screws, and irregular holes) in a single mold, cracking and breakage are significantly reduced. Plus, the precision and surface finish are top-notch, with high product yields and consistent magnetic fields. These magnets also exhibit excellent corrosion resistance.

Applications for injection molded NdFeB magnets are endless, including sensors, brushless motors, automotive electronic throttle pedals, instrument clusters, tachometers, fuel gauges, and more.

| Grade | Remanence | Coercivity | Intrinsic Coercivity | Max. Energy Product | Reversible Temperature Coefficient (RTC) | Max. Working Temperature |

| Br | Hcb | Hcj | (BH)Max | α (Br) | TW | |

| T | KA/M | KA/M | KJ/M3 | %/ ℃ | ℃ | |

| KGs | KOe | KOe | MGOe | |||

| BNI-3 | 0.20-0.40 | 120-240 | 480-640 | 8-24 | -0.15 | 100 |

| 2.00-4.00 | 1.50-3.00 | 6.00-8.00 | 1.00-3.00 | |||

| BNI-4 | 0.40-0.46 | 250-335 | 575-735 | 28-36 | -0.13 | 110 |

| 4.00-4.60 | 3.10-4.20 | 7.20-9.20 | 3.50-4.50 | |||

| BNI-5 | 0.45-0.51 | 280-360 | 640-800 | 37-44 | -0.13 | 120 |

| 4.50-5.10 | 3.50-4.50 | 8-10 | 4.60-5.50 | |||

| BNI-6 | 0.51-0.56 | 295-375 | 640-800 | 44-52 | -0.11 | 120 |

| 5.10-5.60 | 3.70-4.70 | 8-10 | 5.50-6.50 | |||

| BNI-7 | 0.54-0.64 | 320-400 | 640-800 | 51-59 | -0.11 | 120 |

| 5.40-6.40 | 4.00-5.00 | 8-10 | 6.50-7.50 | |||

| BNI-6H | 0.48-0.56 | 335-400 | 1035-1355 | 40-52 | -0.15 | 130 |

| 4.80-5.60 | 4.20-5.00 | 13-17 | 5.00-6.50 | |||

| BNI-5SR (PPS) | 0.45-0.50 | 300-360 | 875-1115 | 36-44 | -0.13 | 150 |

| 4.50-5.00 | 3.80-4.50 | 11-14 | 4.50-5.50 |

Note: The above-mentioned characteristics are related to the shape and size of the magnet, and the performance can only be confirmed based on actual products.

At NGYC, we offer injection molded SmCo magnets, which are produced using advanced injection molding technology. This method enables one-step molding of complex shapes, reducing assembly processes and improving assembly precision. With strong corrosion resistance and high temperature stability, the magnets require no surface treatment.

Applications| Grade | Remanence | Coercivity | Intrinsic Coercivity | Max. Energy Product | Reversible Temperature Coefficient (RTC) |

| Br | Hcb | Hcj | (BH)Max | α (Br) | |

| MT | KA/M | KA/M | KJ/M3 | %/ ℃ | |

| KGs | KOe | KOe | MGOe | ||

| SCI-6 | 520-580 | 300-380 | 640-1200 | 44-52 | -0.04 |

| 5.2-5.8 | 3.8-4.8 | 8.0-15.0 | 5.5-6.5 | ||

| SCI-8 | 600-660 | 360-460 | 640-1200 | 60-68 | -0.04 |

| 6.0-606 | 8.0-15.0 | 8.0-15.0 | 7.5-8.5 | ||

| SCI-9 | 610-680 | 400-480 | 640-1200 | 68-76 | -0.04 |

| 6.1-6.8 | 5.0-6.0 | 8.0-15.0 | 8.5-9.5 | ||

| SCI-3T | 300-400 | 200-280 | 640-1200 | 20-28 | -0.04 |

| 3.0-4.0 | 2.5-3.5 | 8.0-15.0 | 2.5-3.5 |

Note:

1. T refers to isotropic material.

2. Each material grade can be selected with different polymer plastics, such as PA6, PA12, PPS, according to customer requirements.

3. The maximum operating temperatures of different plastics vary: PA6: 150℃; PA12: 120℃; PPS: 180℃."

While the magnetic performance of injection molded ferrite magnets may be lower compared to injection molded NdFeB magnets, their affordable pricing makes them an attractive option for your business. Perfect for use in sensors, electric motors with complex shapes and relatively lower magnetic requirements, our injection molded ferrite magnets are an ideal choice of superior quality and cost-effectiveness.

From high-efficiency permanent magnet DC motors to axial flow fans and variable frequency air conditioner motors, our magnets deliver unrivaled power and performance.

| Grade | Br | Hcb | Hcj | (BH)Max | TW | |

| Remanence | Coercivity | Intrinsic Coercivity | Max. Energy Product | Max. Working Temperature | ||

| MT | KA/M | KA/M | KJ/M3 | ℃ | ||

| EPF-140 | 240 | 180 | 250 | 11.2 | -0.19 | 0.2~0.3 |

| EPF-150 | 250 | 180 | 230 | 12 | -0.19 | 0.2~0.3 |

| EPF-160 | 260 | 180 | 225 | 13 | -0.19 | 0.2~0.3 |

| EPF-160P | 272 | 190 | 230 | 14.2 | -0.19 | 0.2~0.3 |

| EPF-170 | 278 | 190 | 220 | 14.8 | -0.19 | 0.2~0.3 |

| EPF-170H | 278 | 200 | 240 | 15 | -0.19 | 0.2~0.3 |

| EPF-190 | 287 | 187 | 215 | 15.8 | -0.19 | 0.2~0.3 |

| EPF-190H | 290 | 185 | 205 | 16.5 | -0.19 | 0.2~0.3 |

| EPF-200 | 298 | 190 | 200 | 17.1 | -0.19 | 0.2~0.3 |

| EPF-220 | 305 | 180 | 195 | 18.1 | -0.19 | 0.2~0.3 |

| EPF-062K | 105 | 80 | 159 | 1.5 | -0.19 | 0.2~0.3 |

| EPF-102 | 215 | 160 | 27 | 8.5 | -0.19 | 0.2~0.3 |

| EPF-132 | 232 | 175 | 263 | 10.8 | -0.19 | 0.2~0.3 |

| EPF-152N | 260 | 195 | 265 | 13.3 | -0.19 | 0.2~0.3 |

| EPF-172A | 272 | 195 | 235 | 14.5 | -0.19 | 0.2~0.3 |

| EPF-192 | 287 | 190 | 210 | 16 | -0.19 | 0.2~0.3 |

| EPF-192H | 290 | 200 | 235 | 16.5 | -0.19 | 0.2~0.3 |

| EPF-202 | 292 | 200 | 230 | 16.6 | -0.19 | 0.2~0.3 |

| EPF-202F | 285 | 195 | 220 | 16.1 | -0.19 | 0.2~0.3 |

| EPF-212 | 305 | 2.5 | 230 | 18.1 | -0.19 | 0.2~0.3 |

| EPPS-F134L | 305 | 2.5 | 230 | 18.1 | -0.19 | 0.2~0.3 |

| EPPS-F164L | 305 | 2.5 | 230 | 18.1 | -0.19 | 0.2~0.3 |

Contact our specialist to identify a custom solution for your application.